The diaphragm pump (also called a membrane pump) is the culmination of a long history of fluid displacement technology (at least for the time being). It’s come a long way from the likes of Ctesibius’s water organ or Archimedes’ more well-known screw pump. It removes manual labor from the equation, yet moves a variety of fluids at a faster rate.

Like any other piece of industrial-grade equipment, diaphragm pumps are set to receive a slew of upgrades. After all, a projected annual growth rate of 5.2% for the diaphragm pump market until 2034 only makes sense if there’s enough demand. Fortunately, a broad range of factors is driving such a trend, from a rise in practical applications to key innovations.

Improved Performance

Few, if any, would’ve expected that pump technology would be used to move more than just water. Diaphragm pumps possess the power and reliability to move fluids of varying chemical makeups and viscosities—all with the flick of a switch.

As necessity is the mother of invention, improvements in the performance of these positive displacement pumps are inevitable. Experiences of their use in different environmental conditions have resulted in manufacturers introducing a wide range of new features like:

Double Diaphragm Setup

As the term suggests, a double diaphragm setup features two diaphragms instead of one. The extra diaphragm allows a larger volume of fluid to be transferred at a given time. The system’s inner works are also protected from the effects of corrosive chemicals or abrasive fluids.

However, another advantage of this setup is that the pump has a backup diaphragm to fall back on in case the main one encounters an issue. As factories and plants operate 24/7 all year round, the rate of wear and tear on machinery parts increases exponentially. A double diaphragm pump mitigates this risk, which also reduces the risk of downtime.

You can learn more about the nuts and bolts of high-quality diaphragm pumps through online resources like knf.com/en/us. They’re quickly becoming standard across many industrial applications such as chemical processing, food production and beverage processing, and manufacturing.

Industry 4.0 Capability

Experts say the world has experienced at least four Industrial Revolutions throughout its history, the latest being Industry 4.0 (also called 4IR). There’s already talk about Industry 5.0 to be accurate, but it’s still a concept at this point.

Industry 4.0 builds upon the foundation set by its predecessor, featuring practical versions of experimental technologies at the time. At the heart of this movement is data analytics, which has made two crucial innovations possible: artificial intelligence (AI) and machine learning (ML). Long story short, it’s the era of automation.

While diaphragm pumps are already a form of automation, they lack certain features to be fully considered as such until recently. For example, older models lack the ability to maintain consistent flow rates, which is important for displacing viscous liquids. Without the ideal fluid transfer settings, accelerated wear and tear becomes more likely.

Today, diaphragm pumps can be integrated into an Internet of Things (IoT)- ready control system. In addition to configuring a wide range of parameters like flow rate, the system can make AI-assisted adjustments based on the fluid’s properties. Optimal pumping prolongs the pump’s service life and improves energy efficiency.

Industry 4.0-ready diaphragm pumps are perfect for factories and plants seeking to lower their carbon footprint. As environmental awareness grows by the day, production sectors are under pressure to reduce their contribution to emissions. They consume over half of the world’s generated energy and account for one-fifth of global carbon emissions.

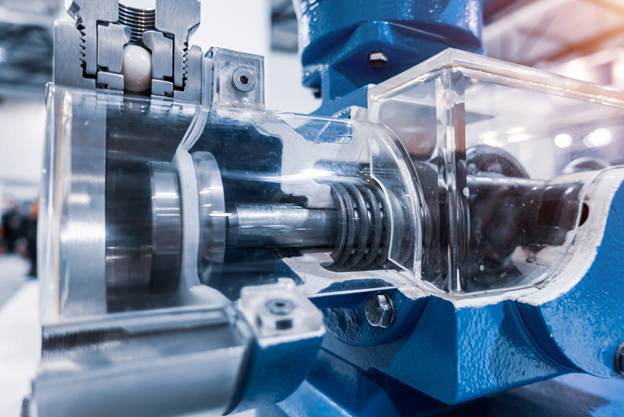

One-Piece or Melded Design

Traditional diaphragm pumps consist of many parts, ranging from metal assembly pieces to rubber or polymer diaphragms. That said, the more components a piece of machinery has, the more points of failure it has.

In this case, nothing incapacitates diaphragm pumps more than fluids seeping into critical joints and orifices. Even when the pump is designed to handle various fluids, it’ll eventually suffer damage from the fluids’ adverse properties. Frequent replacements will eat up a factory or plant’s bottom line quickly.

In light of this, later models have transitioned to a one-piece or melded design. This robust design involves fashioning the pump assembly as a single, continuous piece down to the diaphragm itself. The result is a lower number of points of failure, extending the pump’s lifespan (up to five times, by one estimate).

The Versatility of Diaphragm Pumps

High-quality diaphragm pumps may as well be a staple of modern industries, as it’s impossible to narrow down factories or plants that don’t use any fluids. Be it water for general use or a formula ready for bottling, fluid displacement practically can’t be done without this kind of pump. Otherwise, controlling fluid flow would be time-consuming.

As their usual applications continue to rely on them, diaphragm pumps are also becoming popular across more production sectors. Below are a few examples.

Oligonucleotide Production

Oligonucleotides (often shortened to oligos) in this context refer to synthetic compounds that are modified to treat certain genetic disorders. The healthcare sector has expressed interest in oligos’ potential in treating diseases like polyneuropathy for years. One reason it took this long for it to take off was production limitations in the past.

To create potent oligos, the flow of synthesized solutions must be regulated to the exact parameters. The slightest difference can affect its properties like the concentration level and pH value. A system of diaphragm valves connected to a control system allows users to maintain a proper solution throughout the production process.

Steel Manufacturing

The maximum operating temperature of a diaphragm pump is nowhere near the melting point of iron, let alone steel. That said, it’s still helpful in moving far cooler fluids, not the least of which is a defoamer.

A defoamer is a chemical agent that prevents foam from forming during the steelmaking process. Otherwise, it can result in surface defects that can render entire batches of steel products unsatisfactory. Maintaining a consistent supply of defoamer during steelmaking is well within a diaphragm pump’s capabilities.

Supplement Production

Vitamin powder and certain health supplements are made using a process known as spray drying. It relies on rapid evaporation to turn a sprayed mist of pharmaceutical formula into fine powder. Additional steps then form the powder into tablets or seal it into capsules.

Diaphragm pumps are integral to the spraying portion of the process. As part of a closed system, the pumps have to resist the stresses of firing up the spray tower and be equipped with a hermetic seal to prevent the fluid from contamination. An integrated control mechanism lets users regulate aspects like flow rate and pressure with precision.

Conclusion

Between its up-and-coming features and broadening applications, diaphragm pumps are a valuable asset to modern industries. In a way, they’re the unsung heroes behind practically everything people today can’t live without.