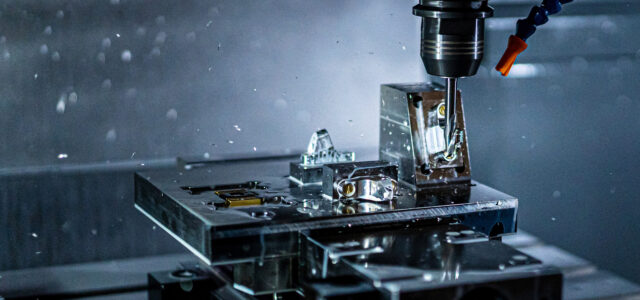

CNC turning technology has revolutionized the way manufacturing takes place. The capability to directly produce complex shapes and corridors has been the driving force behind CNC turning technology, making it an essential tool in prototype manufacturing. The advancements in CNC turning technology have brought significant advancements in perfection, speed, and versatility, leading to better quality and more effective products. In this composition, we’ll explore the rearmost advancements in CNC turning technology and how they’ve impacted prototype manufacturing.

Enhanced Precision

CNC turning technology has always been known for its perfection, but recent advancements have taken it to new heights. With the preface of high-perfection CNC turning machines, the delicacy of the finished product has bettered significantly. These machines can hold for tolerance as tight as ±0.0001mm elevation, making them ideal for the creation of high-quality prototypes. The enhanced perfection allows manufacturers to produce parts that are much more complex, leading to better-performing prototypes.

Advanced Speed

Speed is another critical factor in prototype manufacturing, and CNC turning technology has made great strides in this area. The rearmost CNC turning machines can produce parts at incredibly high speeds, reducing the time it takes to produce a prototype. The use of robotization and robotics has also increased the speed of products by barring the need for homemade labor. The advanced speed not only saves time but also reduces the cost of the product.

Advanced Software

The software used in CNC turning technology has also advanced significantly. The rearmost software allows manufacturers to design complex corridors and shapes with ease. The software can also pretend the product process, allowing manufacturers to descry and correct any implicit defects before the product begins. The use of advanced software has also enabled the creation of custom prototypes, making it possible to produce unique products that were preliminarily insolvable to manufacture.

Lesser Versatility

CNC turning technology has always been protean, but recent advancements have made it indeed more flexible. The rearmost CNC turning machines can work with a wide variety of accouterments, including metals, plastics, and composites. They can also produce parts in a range of shapes and sizes, from small intricate components to large complex structures. The lesser versatility of CNC turning machines has made them an essential tool in a wide range of industries, including aerospace, automotive, and medical.

Integration with Other Technologies

CNC turning technology has also been integrated with other technologies, similar to 3D printing and CAD/ CAM systems. The integration of these technologies has led to higher effectiveness and delicacy in the production process. The use of 3D printing allows manufacturers to produce prototypes snappily and effectively, while CAD/ CAM systems enable the design of complex parts with ease. The integration of CNC turning technology with other technologies has made the production process more streamlined and effective.

In the end

the advancements in CNC turning technology have brought significant improvements to prototype manufacturing. The enhanced precision, advanced speed, and advanced software have all contributed to better quality and more effective products. The lesser versatility of CNC turning machines has made them an essential tool in a wide range of industries, while the integration with other technologies has made the production process more streamlined and effective.

With these advancements, manufacturers can now produce prototypes that are much more complex and high-quality than ever before. The use of robotization and robotics has also reduced the time and cost it takes to produce a prototype, making the process more efficient. Moreover, the advanced software used in CNC turning technology has enabled the creation of custom prototypes, allowing for the production of unique products that were previously impossible to manufacture.

As the demand for high-quality and complex prototypes continues to grow, CNC turning technology will undoubtedly continue to evolve and improve. With the continued advancements in technology, it’s exciting to think about the possibilities of what can be achieved in the world of prototype manufacturing.